Okay, so today I wanna talk about this thing called a “co-axial escapement movement.” Sounds fancy, right? Well, it kinda is, but it’s also pretty cool once you get what it’s all about. I got into this whole thing because I wanted to try fixing my watch myself. Then I saw this watch had some special parts inside.

So, first thing I did was try to open my watch. It was tough, man! But after watching some videos online and a lot of carefull work, I finally got it open. Inside, there’s this whole system of gears and tiny parts. It was a mess of complexity. I was like, “Whoa, how does this even work?”

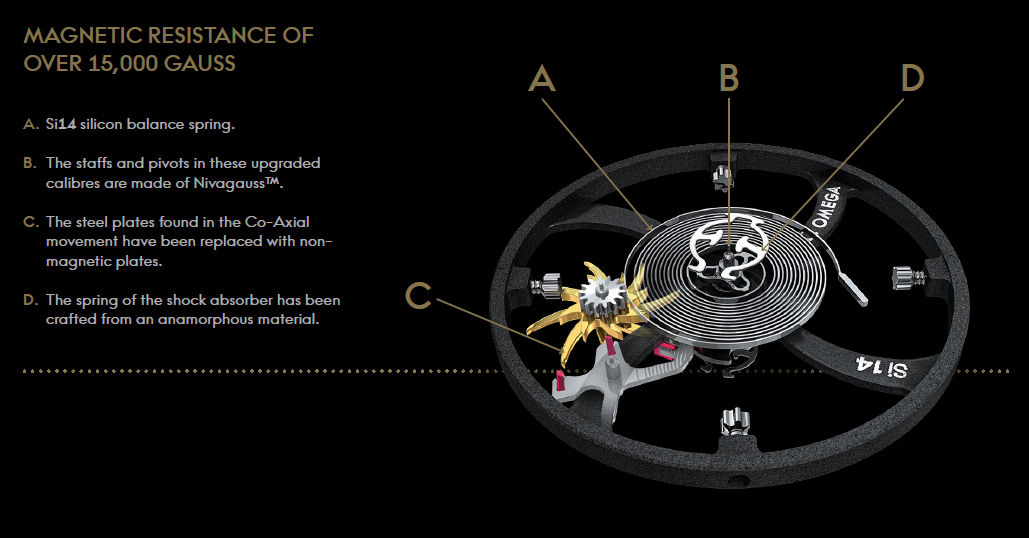

Then I started looking into what makes a watch tick, literally. That’s when I stumbled upon this co-axial thing. Turns out, it’s a special way that some watches are built to keep time more accurately. It’s like, instead of the parts rubbing against each other and wearing down, they’re designed to push in a way that there’s less friction. They used a word called “radial friction” instead of “sliding friction” to describe it. Made sense once I saw it in action.

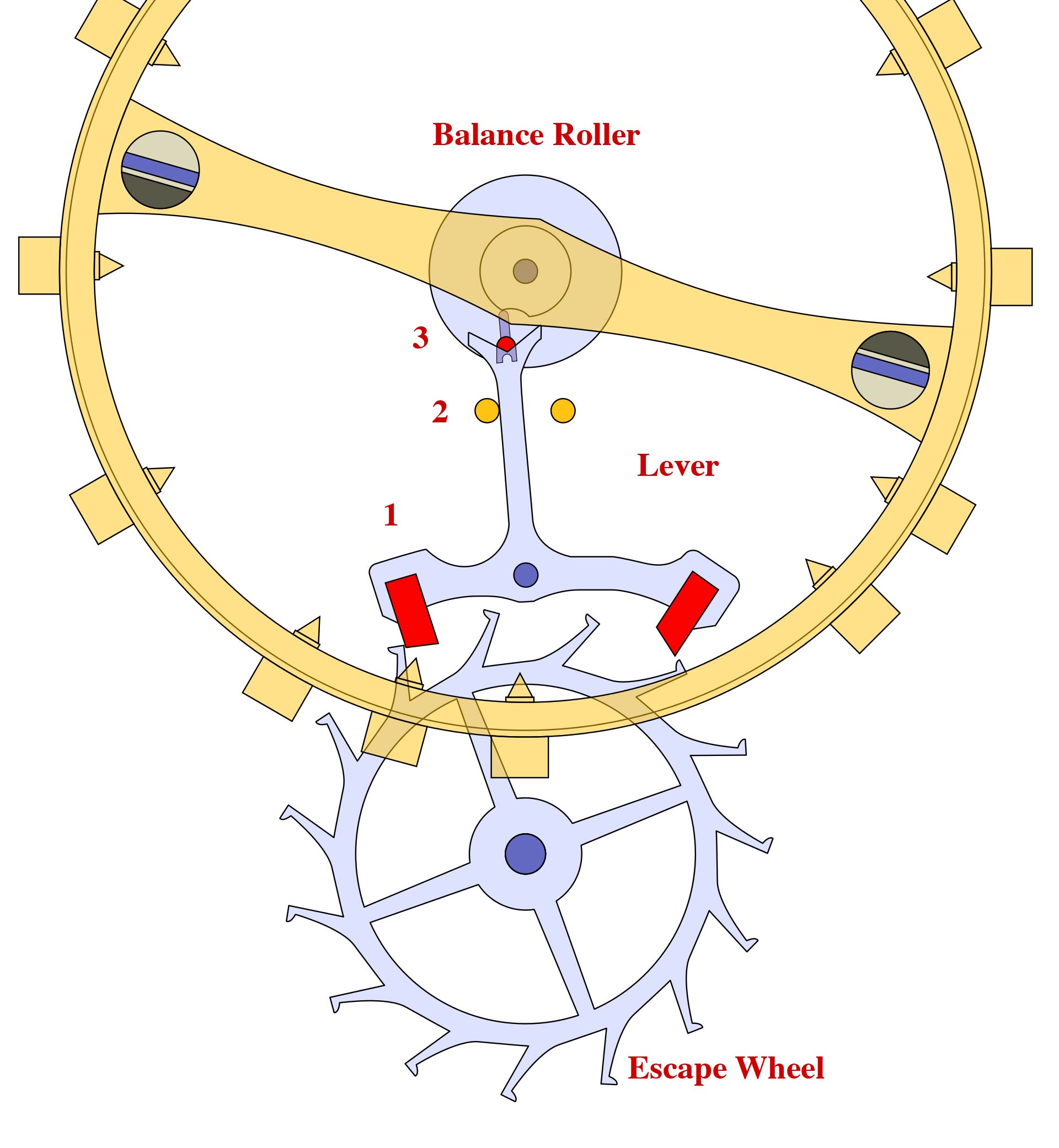

I spent a bunch of time looking at diagrams and videos, trying to get how this thing worked. This guy, like 250 years ago, came up with the idea, but it was way too hard to make back then. Now, with all our fancy machines, it’s doable. So, they use three of these things called “pallets” to separate out the locking mechanism from what makes the watch move, calling it the impulse. Smart, right?

Here’s how I saw it work:

- I found the escapement wheel. This is the heart of the whole thing, and it looks different in a co-axial setup.

- I noticed the pallets. There are three of them, and they interact with the escapement wheel in a special way.

- I traced the movement. Instead of just sliding, these pallets push the escapement wheel. This reduces the rubbing and, they say, makes the watch more efficient.

After all this, I tried putting my watch back together. I took my time, making sure each part was in the right place. I broke a few things, but I learned from that. It was a long process. Once I got it all put together, I wound it up and… it worked! I was so stoked, man. It wasn’t perfect, but it was ticking, and that was a huge win for me.

This whole co-axial escapement thing showed me how complicated watches are. It’s not just about telling time; it’s about engineering and design. And it’s definitely something I wanna learn more about. Maybe I’ll even try building my own watch someday, who knows?