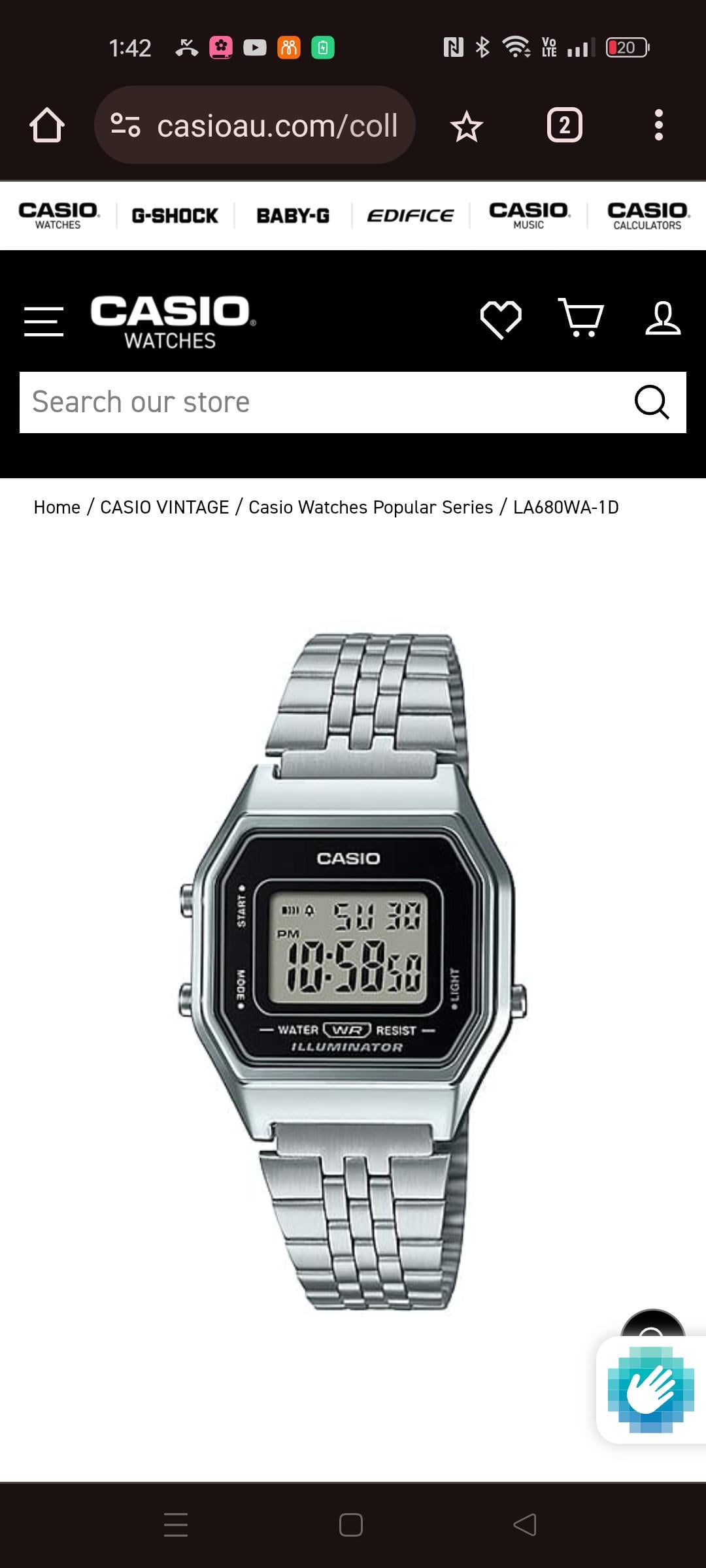

Alright, so I got this bug in my ear a while back, you know? Kept thinking ’bout this thing I started calling “Casio Ultra” in my head. Wasn’t about buying some new fancy model, nah, this was all me, my workbench, and a classic Casio that’s seen better days. The idea was to take a perfectly good, simple watch and, well, make it more. More rugged, more mine.

Getting Started on This Madness

First thing, I dug out an old G-Shock I had. One of the basic ones, tough as nails already, but I figured, why not push it? My plan wasn’t super complicated, or so I thought. Reinforce the casing a bit more, maybe try to improve the water resistance beyond factory specs, and add a super bright, custom LED backlight because the stock one always felt a bit weak to me. That was the “ultra” part for me.

So, I ordered some specific epoxy resin, the kind they use for boat repairs, thinking that’d do the trick for the casing. Also got a few different tiny LEDs and some fine gauge wire. Felt like I was prepping for surgery on a flea, everything was so small.

The Messy Middle

Taking that G-Shock apart, that was the first hurdle. Those screws are tiny, and they really don’t want to come out. I must’ve spent a good hour just getting the backplate off without stripping anything. Then, the real “fun” began. I wanted to carefully apply a thin layer of that epoxy inside certain parts of the shell, for extra shock absorption. Sounds easy, but that stuff is sticky, gets everywhere, and you’ve got a limited time before it sets. My fingers were covered.

- Managed to get a super-thin coat on the inside. Looked okay.

- Then, tackling the old light. Desoldering that tiny bulb was a nightmare. My hands aren’t as steady as they used to be, I tell ya.

- Trying to solder the new, brighter LED in? Let’s just say there were a few choice words muttered. The contact points are minuscule!

It kinda reminded me of this one time I tried to fix my kid’s remote control car. Thought it’d be a quick job, open it up, re-solder a wire. Two hours later, car’s still busted, and I’ve got plastic bits all over the kitchen table. Sometimes simple ideas just spiral, you know?

Pushing Through the Frustration

There was a point where I nearly just threw the whole mess in a drawer. The new LED wasn’t sitting right, and I was worried I’d damaged the module trying to get it in. But, I’d already called it “Casio Ultra” in my project notes, so I felt like I had to see it through. Stubborn, I guess.

So, I took a break, made a cup of tea, and came back with fresh eyes. Decided to try a slightly different angle for the LED, and what do you know, it finally clicked into place. Carefully got the wires soldered, heart in my mouth hoping I hadn’t fried the whole circuit.

The “Ultra” Reveal… Sort Of

Putting it all back together was another exercise in patience. Getting that rubber gasket to sit perfectly, making sure all the screws were tight enough for water resistance but not so tight they’d strip. Finally, it was all assembled. I pressed the light button.

And it worked! The new LED was definitely brighter, a nice clear white instead of that dim greenish yellow. The epoxy seemed to make the whole thing feel even more solid, though that might have just been in my head. I dunked it in a bowl of water for a good ten minutes, and no leaks. Success!

So, my “Casio Ultra” project didn’t end up with laser beams or anything, but it was a good test of patience. The watch is still ticking, it’s a bit tougher, and the light is way better. It’s my own custom version, and that’s pretty cool, I think. It’s not something Casio would ever release, but it’s my ultra. Learned a lot, mostly about how tiny watch parts are and how much I dislike sticky epoxy on my fingers. But hey, that’s the fun of tinkering, right?